The importance

of planning and practicing drills cannot be understated. The Aluminium Plant

Safety Blog posted incidents where previous planning and drills resulted in

zero injuries. On the other hand we have also posted incidents where workers

were either injured or killed and a lack of planning and drills may have been a

contributing factor. On our site visits around the globe one question that we

will ask a shop floor worker is “when was your last drill?” A majority of the

times the worker answers immediately with a date.

We acknowledge

that the planning and coordination of the drills is time consuming and

difficult to quantify the benefits. Regardless, it is well worth the time and

expense to make sure your workers know instinctively what to do when an

emergency occurs. As the APSB has shown over the course of our short history

that incidents can occur throughout the day and night without warning.

Many in our industry

have expanded their plant drills to include local emergency management services

as well as local hospitals. Here is a recent story:

At 9:15 a.m. Thursday, Aug. 27,2015 emergency signals began sending out

on a simulated chemical spill at Logan Aluminum. This was an exercise only, one

held to better prepare emergency services to handle possible disastrous events

if they ever transpire.

The mock drill involved the Logan Aluminum Fire Department, Logan County

Emergency Management, Russellville City and Rural Fire Departments, Lewisburg

Fire Department, Logan County Emergency Communications Center (ECC), Logan

County EMS and Logan Memorial Hospital.

“The drill went really well,” said Terry Cole of Emergency Management.

“We have had several of these drills over the years and they help us prepare

for the real thing.”

Simulating a real event is necessary to polish disaster plans. Working

through the process of what an event will entail and what resources you need

can better prepare you if an actually event really occurs.

These types of drills allow responders to try to work together in

scenarios that are as close to the real thing as possible. The drills allow the

responders to find and iron out the problems that can occur as multiple

agencies try to coordinate responses to big events. They allow for physically

going over what will happen when a disaster hits. In this way, there will be

less of a surprise, and more importantly, those involved will know what to do.

Drills also allow for there to be new ideas and make more effective plans if

they are needed, as well as making sure that all emergency equipment actually

works and is ready.

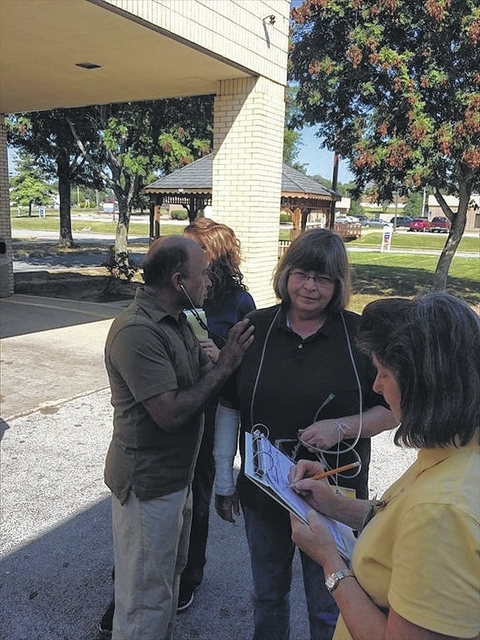

When the call came into the ECC of the simulated chemical spill at Logan

Aluminum, all agencies were notified and responded accordingly. Nine mock

patients were involved, some with exhaustion and some with chemical burns.

Those at Logan Aluminum immediately began setting up an incident command center

where patients were evaluated and decontaminated preparing for transport to

Logan Memorial Hospital.

Logan County has a group of business people and emergency service

professionals that make up the Local Emergency Planning Committee (LEPC). This

group is constantly working on emergency plans for the county and learning what

works best for those who live here.

“We always plan for the worse case scenario during these drills,” said

Russellville Rural/Logan Aluminum Fire Chief Cheryl Allen. “These drills help

emergency services all work together for one common goal. After the drill is

over, we all get together and discuss what could have been done better and what

should we implement in the future.”

Allen and Cole both commended those involved in the drill.

“Logan Memorial Hospital did a great job,” said Cole. “Joyce Noe- who

serves on the LEPC- is very knowledgeable on what needed to be done at the

hospital.”

Noe is the Director on Infectious Control, Employee Health,

Environmental Services and Emergency Management for Logan Memorial Hospital.

“The drill went very well,” said Noe. “Logan Memorial participates in

these drills because it helps to prepare us, as well as creates strong

relationships between emergency response teams in our county.”

Noe said the drills help to improve everything from response time to

knowing what can be improved upon.

“As a hospital, we want to be prepared. We want to assure those in our

community that we are doing the best we can. By participating in these

emergency drills, we can make sure we are ready in case the community needs

us.”

The Aluminium Plant Safety Blog would like to congratulate Logan Aluminium

and all of the emergency management service organizations that participated in

this drill. It is our hope that a reader will view this post and say “Hey look

what Logan Aluminum did, we should think about doing something like that.”

Every plant should actively reach out to local emergency management service organizations

for plant tours and education about the hazards that are within your plant. The

Aluminium Times had an article about just this topic:

No comments:

Post a Comment